For us, modular construction means more than just creating spaces. With our modular system, we combine precision and efficiency with responsibility for the environment and society. The construction industry is entering a new chapter: we show how technology, sustainability and creative power can be combined into a single entity. Buildings are constructed faster, more precisely and with a smaller ecological footprint. Above all, however, spaces are created that remain adaptable, can be tailored to people's needs and will last for generations. In this way, construction becomes a driver of progress – responsible, efficient and forward-looking.

Sustainability means taking responsibility today and laying the foundations for the future. Our modular plug-in and screw system is used to create buildings that are efficiently planned and implemented from the outset. The materials used are carefully selected, designed for a long service life and contribute to a resource-saving, CO₂-neutral construction method. At the end of their useful life, the buildings can be almost completely dismantled and returned to the material cycle. Many modules can even be reused directly elsewhere. This is how circular construction becomes a living practice – a closed cycle that conserves resources and creates lasting value for future generations.

Our patented plug-in and screw system forms the basis of our modular construction method. It ensures precision in every detail and enables quick, safe assembly. The simple plug-in system also makes electrical installation much easier and can be implemented without complex work steps. Because it is so easy to use, people from different fields and with different backgrounds can actively participate in the construction process. In a time of skilled labour shortages, this technology creates new opportunities and makes the construction process accessible to everyone.

Time is one of the most valuable resources in construction. Our modular system ensures that projects start without delay, run according to plan and are completed on schedule. Prefabrication in controlled processes speeds up the entire process and makes it independent of external conditions. This results in buildings that can be used more quickly while ensuring the highest precision and quality.

Whether for residential buildings, offices or public facilities, our modular system allows for flexible floor plans and adapts to a wide range of requirements. Modules can be dismantled, recombined or used elsewhere as needed. At the same time, buildings can be easily adapted to future comfort and design standards without the need for major structural alterations.

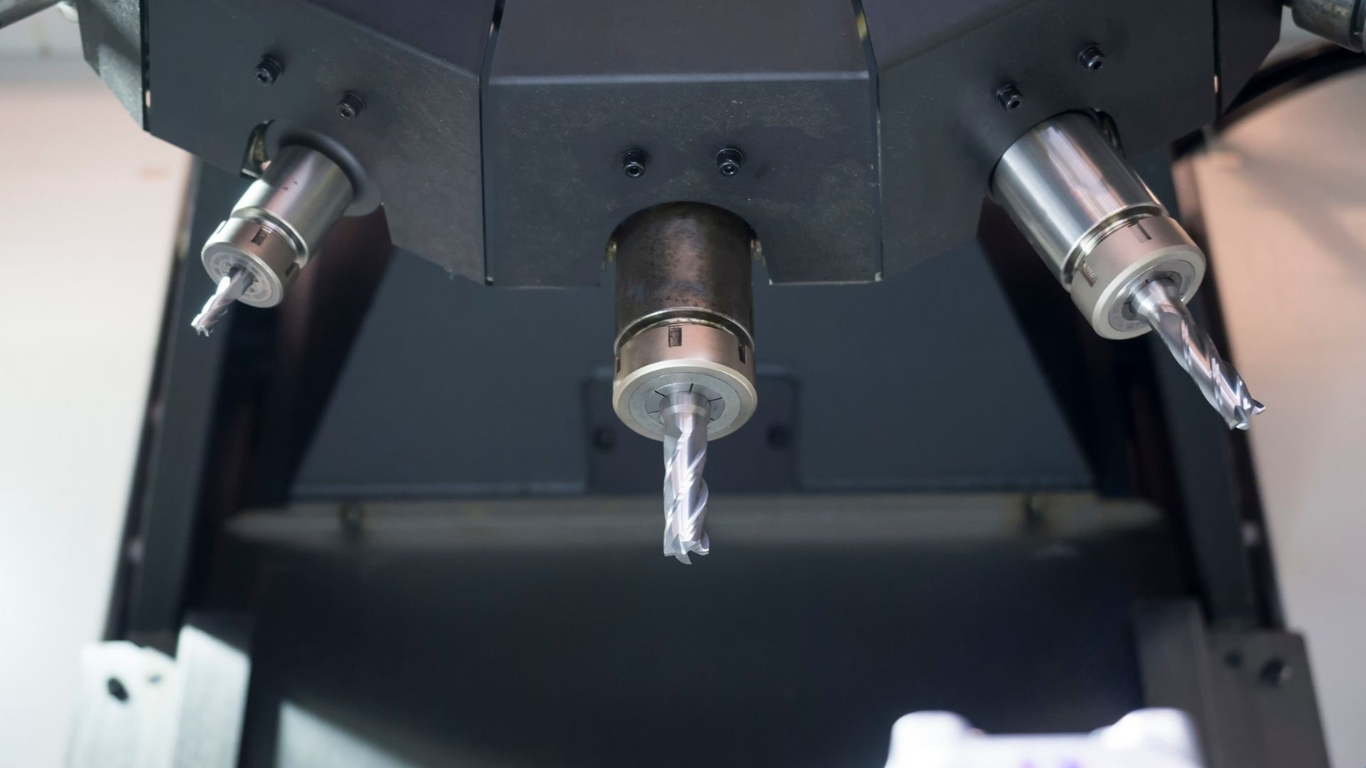

Quality does not happen by chance, but through precision at every step. In our production facilities, modules are manufactured under controlled conditions and by trained specialists who guarantee precision work down to the last detail. Each element is manufactured with millimeter precision and adapted exactly to our customers' specifications. This is how we ensure consistently high standards that our customers can rely on.

Our modular buildings are not only manufactured with precision, but also independently tested. Type testing by ift Rosenheim confirms that they meet the highest safety and stability requirements. In addition, they are tested for earthquake safety – proof that our construction method can withstand even extreme conditions. At the same time, the system is so load-bearing that even buildings with up to 50 floors can be realised.